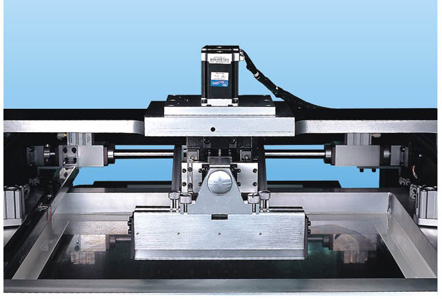

1The scraper system

D - D3 system is the third generation of direct type scraper system, this system is composed of two independent knife head.Every knife head is directly driven by a high precision stepper motor.Traditional pneumatic type or synchronous belt drive the knife head cannot meet the accuracy requirement of the latest SMT process.With D - D3 system, squeegee pressure can be precise measurement and control."Self balancing scraper can automatically adapt to the surface of the steel net, enables the solder paste to accurate, uniform printed on the PCB, solder paste surface more smooth and pasted on the effect.

D - D3 system also can help to improve the process of PCB to take off the membrane, rely on D - D3 system of scraper in PCB, separating from the stencil to release the pressure of scraper, before making stencil in flat to take off the membrane process, prevent to take off the membrane in PCB process of steel net for bending stress is not the average any influence on the position of the solder paste shape.

Scraper self-protection system is D - D3 scraper system of a proprietary features, under this system, scraper head of the spring system can absorb excessive squeegee pressure, scraper and steel toil will not damage because of the pressure setting is too large.

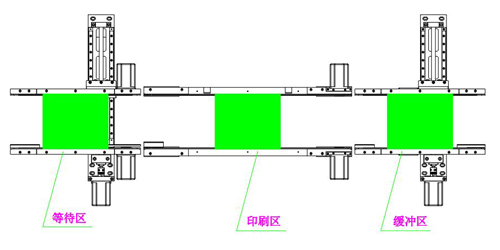

2 Accurate transport system

PCB transmission system is driven by stepper motor, stepper motor "smart" more than ordinary dc motor, it transmit the PCB process into two stages, in the first stage to transmit the PCB at full speed, when the PCB near the damper device, stepper motor slowdown in order to prevent the PCB hit the dampers.Under this new type of transmission system, each PCB can be transmitted to the fastest speed.

3.Splint positioning system

A special way of fixed clamping system can more solid than traditional way can work for a long time and keep the printing accuracy, regardless of the single side, double side or different thickness of the PCB, we can easily deal with the clamping system.Side clamp system capable of handling the vast majority of PCB, and Z to PCB clamping system can effectively deal with bending of PCB.

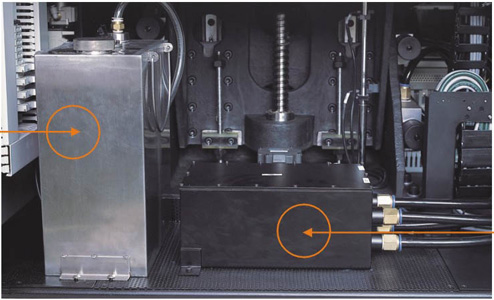

4.Stencil cleaning systems.

According to the different situation, engineering personnel can be set freely: dry clean, wet wipes, vacuum cleaning and so on three different combinations to clean the bottom of the steel net, wiping paper by two special design pressure tube sealed pressure at the bottom of the steel net, wipe the paper and the "soft" between the stencil exposure can effectively and reliably remove any residue on the surface of the steel net, tin powder.

Cleaning system directly from both ends of a vacuum tube in vacuum pump, combined with the special designed vacuum tube cavity, there is a strong enough to ensure that the vacuum tube and the average of vacuum suction.